Logimax’s Inventory Management Solutions: Control and Visibility

Warehouse inventory management is more than just tracking goods; it’s about having the right information at the right time to make informed decisions. Logimax’s warehouse inventory management software provides that clarity, offering a 360-degree view of your inventory. With real-time tracking, customizable reporting, intelligent forecasting, and seamless integration with other systems, Logimax empowers you to take control of your inventory like never before. Whether it’s managing multi-warehouse operations, analyzing turnover trends, or generating customer-specific documents, Logimax’s system provides the tools you need to master inventory management. Embrace the future of inventory control with Logimax, and discover how our technology can transform your warehouse operations.

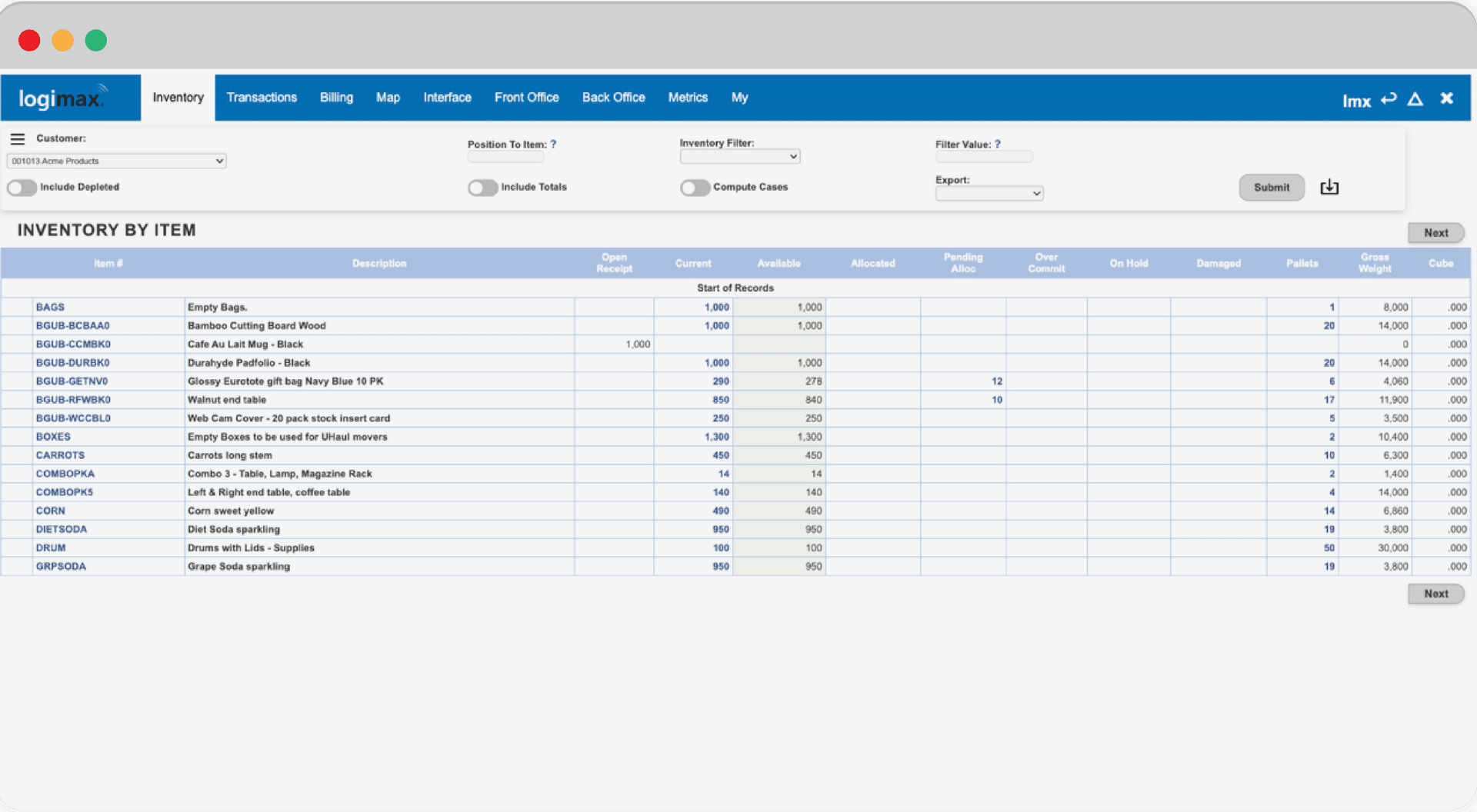

Real-Time Inventory Tracking

Logimax’s real-time inventory tracking provides immediate visibility into stock levels, locations, and status across multiple warehouses. By offering a live snapshot of your inventory, this feature enables quick decision-making, reduces stockouts, and enhances overall warehouse efficiency. It’s an essential tool for maintaining accurate inventory records and responding to dynamic market demands.

Full Barcode Tracking

Ensure accuracy and efficiency with full barcode tracking. Logimax’s system supports various barcode formats, allowing for seamless scanning and tracking of items throughout the warehouse. This feature reduces manual errors, speeds up the warehouse inventory management process, and integrates with other systems for a cohesive tracking solution, making it a cornerstone of modern warehouse operations.

Lot, Serial Number, & Expiration Control

Maintain complete traceability with lot and serial number, production, and expiration date control. Logimax’s warehouse inventory management software provides detailed tracking and reporting capabilities, supporting quality assurance, compliance, and efficient recall management. This feature ensures that every item’s history is accessible, enhancing accountability and supporting various industry regulations.

Multi-Warehouse Inventory Support

Coordinate inventory management across multiple warehouse locations with Logimax’s integrated system. This feature provides centralized control and coordination, ensuring consistency and efficiency in multi-warehouse operations. Whether you’re managing regional distribution centers or global supply chains, Logimax’s system offers the flexibility and control needed to optimize inventory across various locations.

Temperature-Controlled Inventory Management

Manage temperature-sensitive goods with precision using Logimax’s temperature-controlled inventory management feature. Ensure products are handled and stored according to specific temperature requirements, maintaining quality and compliance. This specialized solution caters to industries like food and pharmaceuticals, providing accurate temperature monitoring and control throughout the inventory lifecycle.

Automated Replenishments

Automate replenishment processes with Logimax’s intelligent system. Define min/max levels, and let the software handle the rest, ensuring optimal stock levels and reducing the risk of stockouts or overstocking. This feature leverages real-time data and predictive analytics to maintain the right balance of inventory, supporting efficient operations and customer satisfaction.

Cycle Counting and Physical Inventory

Conduct efficient cycle counting and physical inventory with Logimax’s streamlined tools. Schedule counts, manage discrepancies, and maintain accurate inventory records without disrupting daily operations. This feature supports regular audits and compliance checks, ensuring that inventory data is always accurate and up to date.

Hold/Release/Damage Management

Effectively manage hold, release, and damage statuses within the inventory process. Logimax’s comprehensive system provides flexibility and control, allowing for various scenarios and compliance requirements. Whether it’s quality checks, regulatory holds, or damage assessments, this feature ensures that goods are handled appropriately throughout their lifecycle.

Visual Map Storage Configuration

Utilize visual map storage configuration for intelligent space utilization. Logimax’s graphical representation of warehouse layout aids in optimizing storage locations, enhancing efficiency, and reducing operational costs. By offering a clear view of storage availability and utilization, this feature supports strategic planning and maximizes warehouse space.

Inventory Turnover Trends Analysis

Analyze inventory turnover trends with Logimax’s advanced analytics. Identify patterns, optimize turnover rates, and make informed decisions to enhance inventory performance and profitability. This feature provides insights into how inventory moves through the warehouse, helping you identify opportunities for improvement and align strategies with business objectives.