Transforming Data into Action with Logimax’s Warehouse Metrics & Reporting

Data is the lifeblood of modern warehouse operations, and Logimax’s warehouse metrics and reporting tools are designed to harness its power. With features like executive dashboards, user KPIs, notifications, and trend analysis, Logimax’s reporting system provides a 360-degree view of your warehouse operations. Whether monitoring dock-to-stock times or analyzing receiving trends, Logimax offers the tools to transform data into actionable strategies. Elevate your warehouse management with Logimax’s advanced reporting and warehouse metrics.

Executive Dashboard

Logimax’s executive dashboard offers a comprehensive, high-level view of warehouse operations. Customize the dashboard to display vital KPIs, trends, and real-time data, enabling executives to monitor performance, identify opportunities, and make informed strategic decisions. This feature fosters a data-driven culture, aligning operations with business goals.

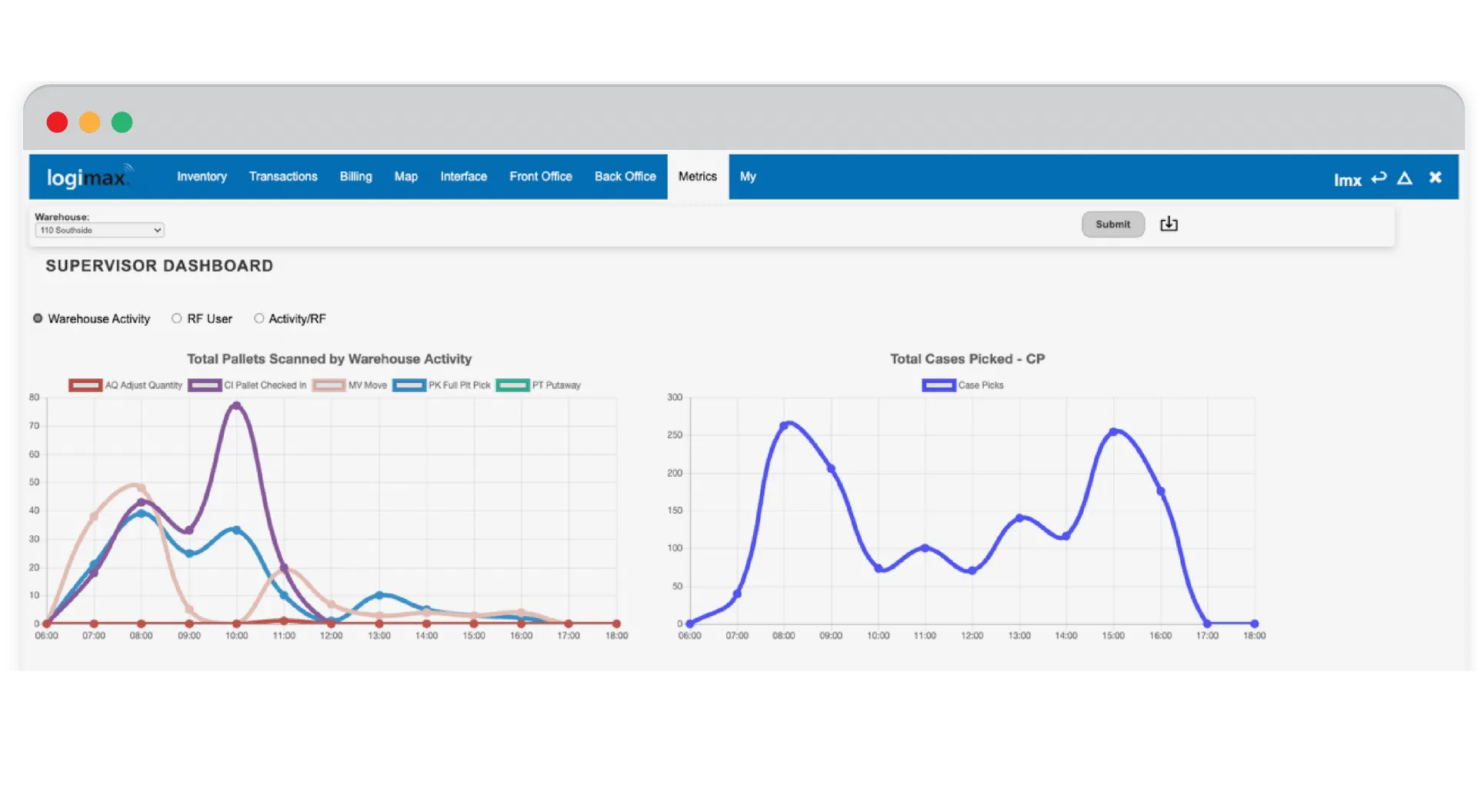

Warehouse Supervisor Dashboard

Tailored for warehouse supervisors, this dashboard provides in-depth insights into daily operations. From tracking inventory levels to monitoring staff performance, supervisors can access real-time data to manage resources effectively. This feature enhances operational oversight, promoting efficiency, and continuous improvement.

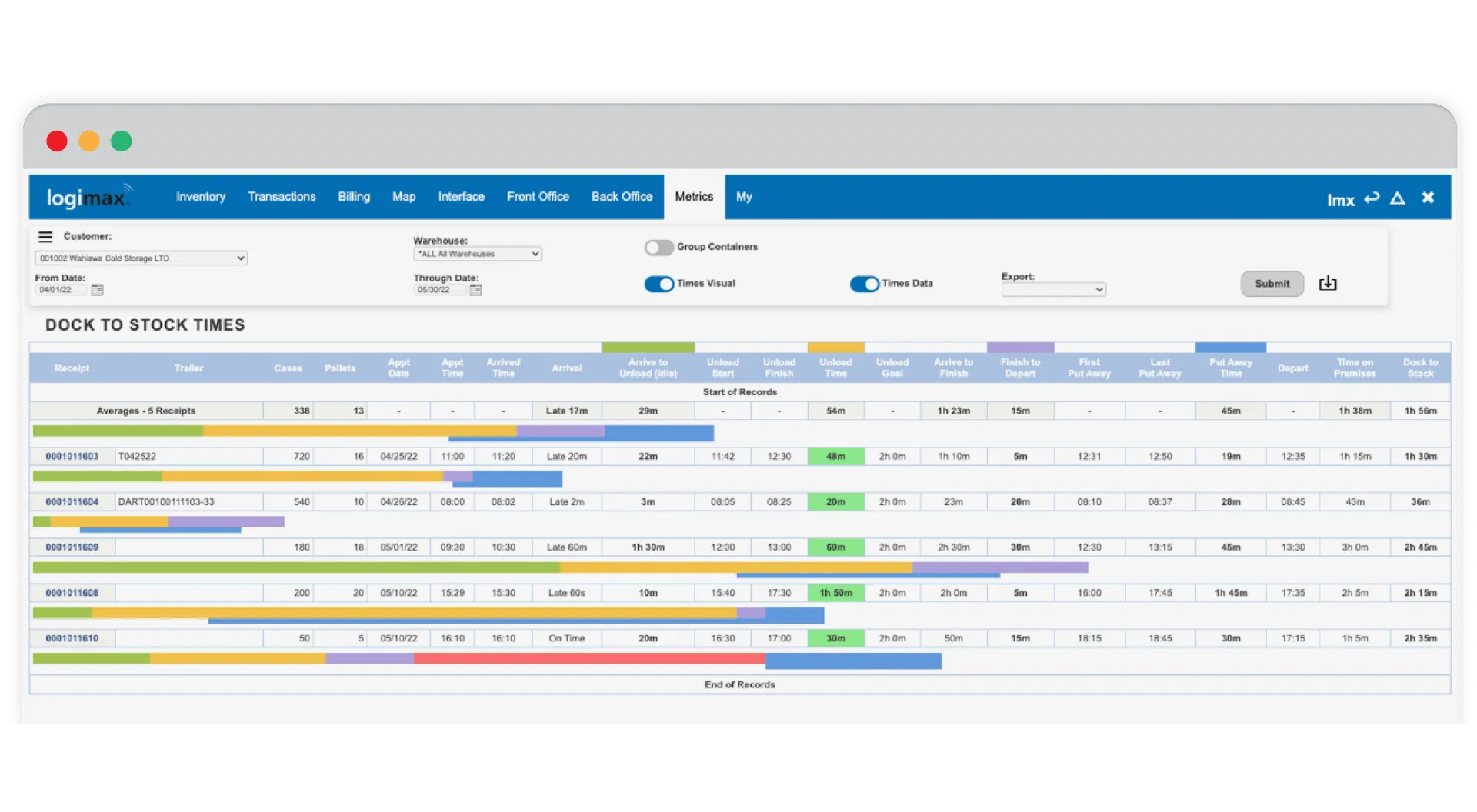

Dock To Stock Metrics

Analyze dock-to-stock times with precision using Logimax’s specialized reporting feature. Track the efficiency of receiving and putaway processes, identify bottlenecks, and implement improvements. This metric is essential for reducing lead times, optimizing workflows, and enhancing overall warehouse efficiency.

Pick To Ship Metrics

Logimax’s pick-to-ship metrics provide detailed insights into picking and shipping processes. Analyze efficiency, identify areas for improvement, and streamline order fulfillment. This feature supports faster order processing, enhances customer satisfaction, and contributes to a lean and agile order management process.

Receiving, Putaway, and Picking KPIs

With user-specific KPIs for your warehouse operations, Logimax’s system offers detailed insights. Managers can identify areas for improvement, recognize top performers, and optimize resource allocation. This feature supports process optimization, enhancing efficiency, and accuracy in receiving, putaway and picking tasks.

Cycle Count KPIs

Monitor cycle counting effectiveness with specialized KPIs. Analyze accuracy, efficiency, and trends, supporting continuous improvement in inventory management. This feature ensures that cycle counts align with inventory goals, enhancing accuracy, and reducing discrepancies.

Inventory Turnover Trends

Track inventory turnover trends to optimize purchasing decisions and reduce excess stock. Analyze how quickly inventory is sold and replaced, maintaining optimal levels. This feature is vital for improving cash flow, reducing carrying costs, and aligning inventory with sales trends.

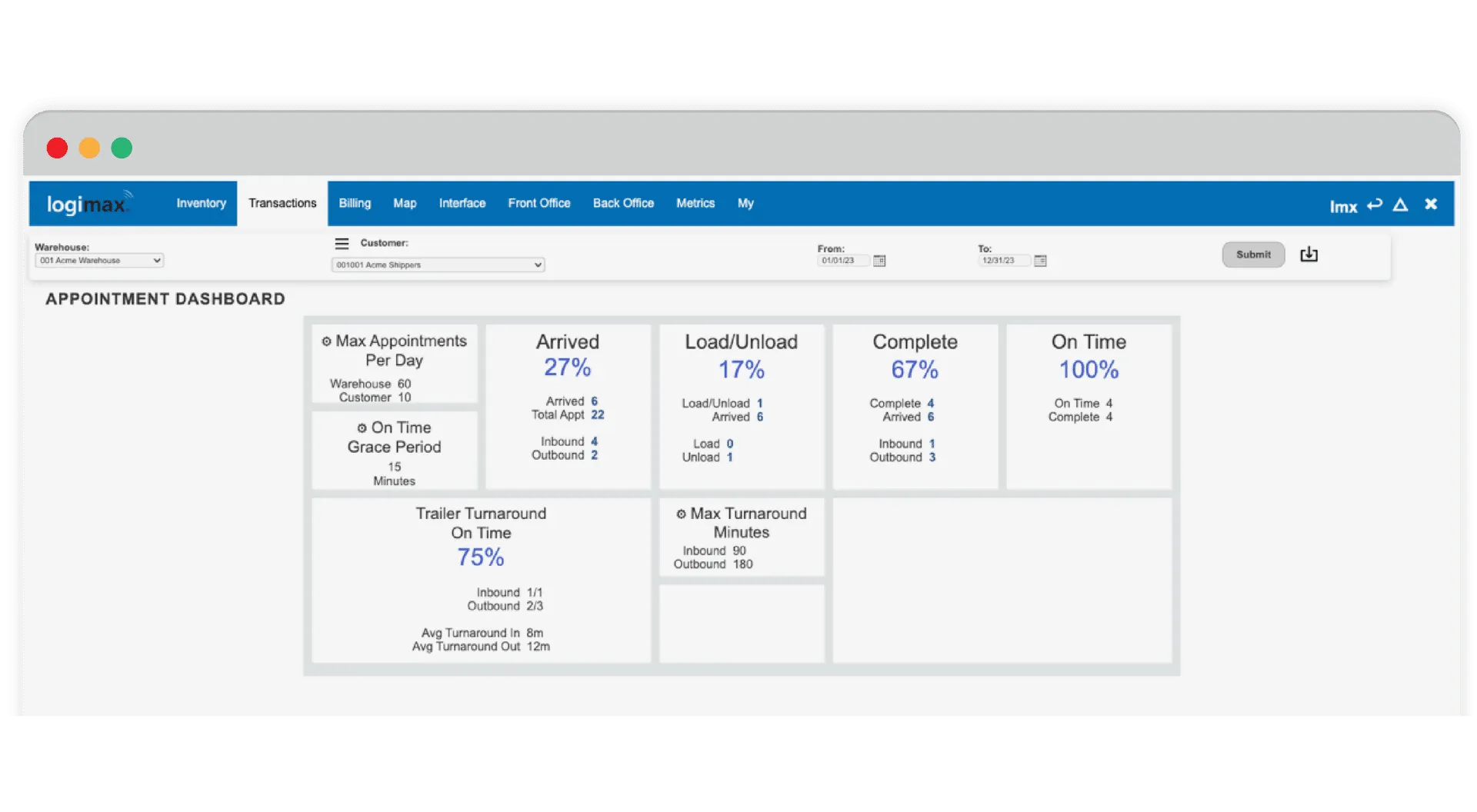

Carrier Appointment KPIs

Track carrier appointment performance with specialized KPIs. Gain insights into carrier punctuality, efficiency, and compliance, enhancing collaboration, and improving shipping processes. This feature fosters strong carrier relationships, ensuring timely and cost-effective shipping.

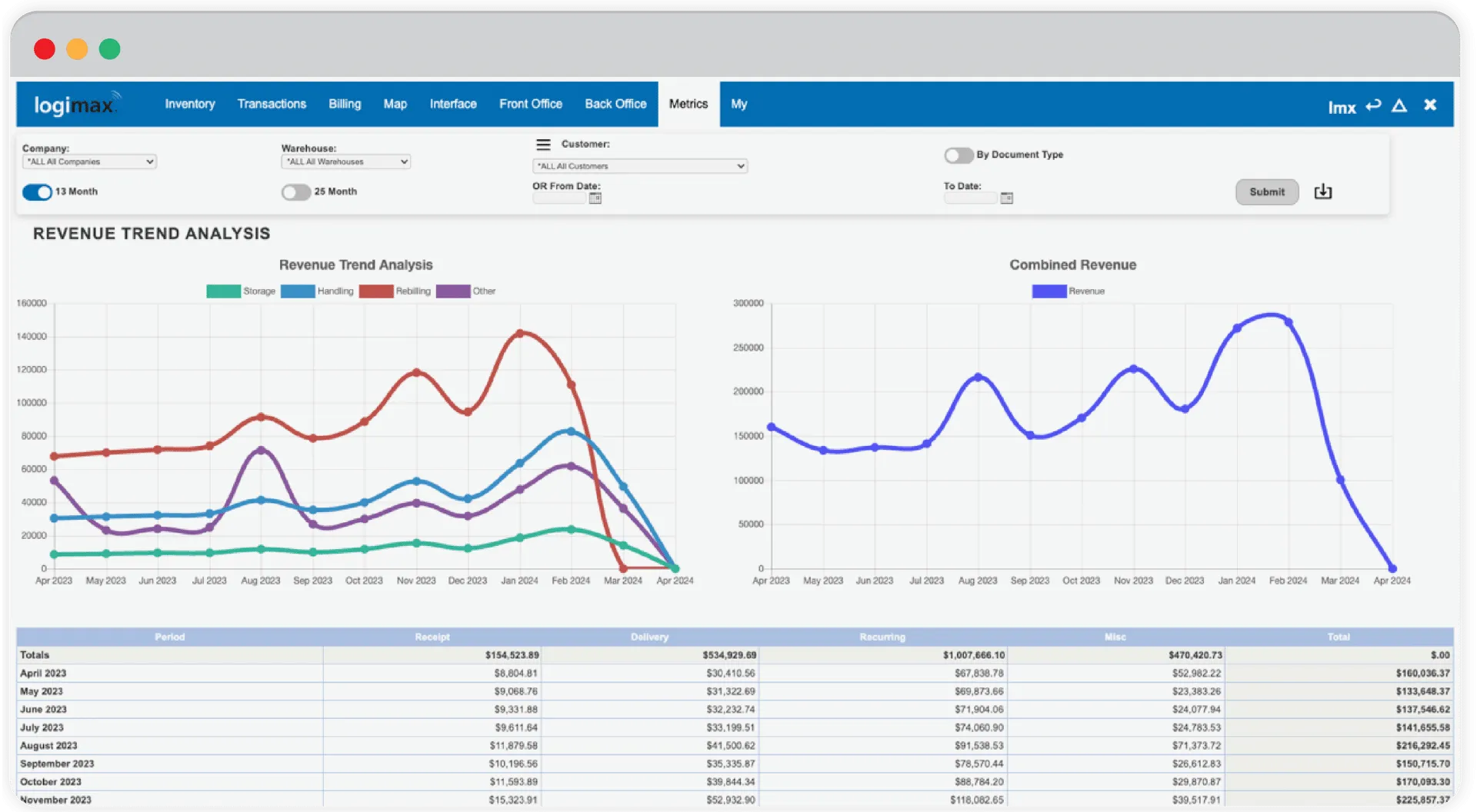

Revenue Trends by Company, Warehouse, Customer, Item, Charge Code

Analyze revenue trends across various dimensions for strategic planning and optimization. Gain granular insights into revenue performance, identify opportunities, and align sales strategies with market trends. This feature supports revenue growth, customer segmentation, and targeted marketing efforts.