Uncover the secrets of 1D barcode technology in our comprehensive guide.

1D barcode technology has revolutionized the way we track and manage information. From retail businesses to libraries and ticketing systems, barcodes have become an essential tool in modern society. In this comprehensive guide, we will delve into the world of 1D barcode technology, exploring its history, functionality, and various applications. By the end of this article, you will have a solid understanding of how 1D barcodes work and how they can benefit different industries.

Understanding 1D Barcode Technology

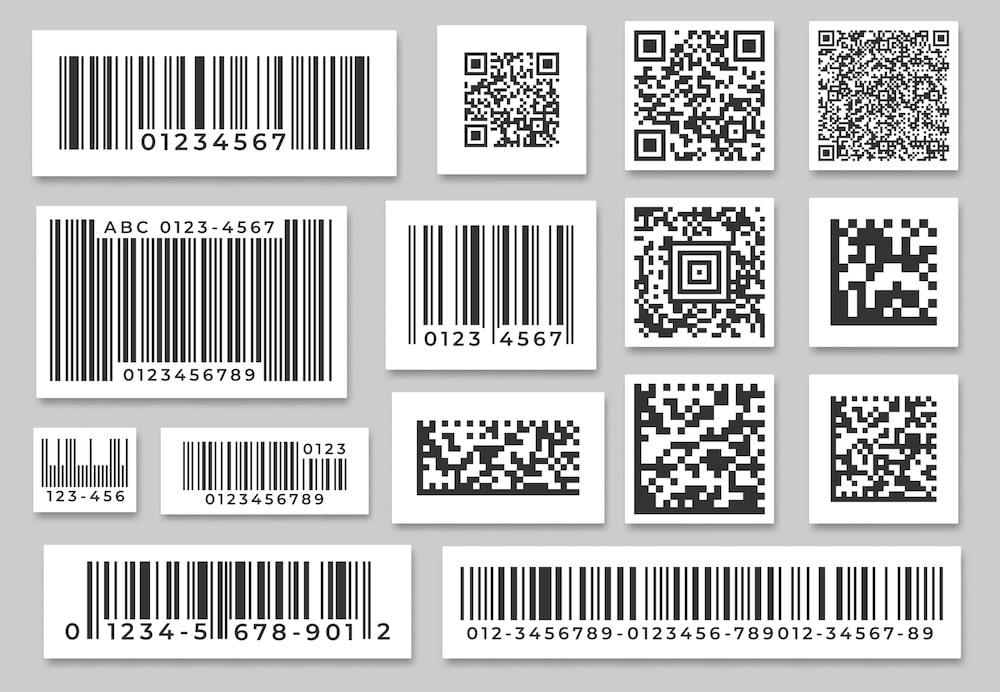

Before we dive into the intricacies of 1D barcode technology, let’s start with the basics. What exactly is a 1D barcode and how does it function? Simply put, a 1D barcode is a linear representation of data that can be scanned by a barcode reader. It consists of a series of black and white bars of varying widths, which encode specific information.

The Basics of 1D Barcodes

At its core, a 1D barcode is comprised of two main components: the barcode symbology and the human-readable interpretation. The barcode symbology determines the encoding method used to represent data, while the human-readable interpretation displays the encoded information in a format that can be easily understood by humans.

One of the most widely used barcode symbologies is the Universal Product Code (UPC), which is commonly seen on retail products. UPC barcodes consist of 12 digits, divided into two parts: the manufacturer code and the product code. The human-readable interpretation of the barcode displays the numbers below the barcode, allowing store clerks to manually enter the code if needed.

Key Components of 1D Barcodes

When examining a 1D barcode, you will notice several important elements. First, there’s the start and stop characters, which serve as the barcode’s beginning and end. These characters help barcode readers identify the barcode’s boundaries.

Next, there’s the quiet zone, a clear space located at the beginning and end of the barcode. The quiet zone ensures that the barcode reader can distinguish the barcode from its surroundings, minimizing errors during scanning.

The bars and spaces within the barcode represent binary data. Black bars typically represent the number 1, while white spaces represent the number 0. By decoding the pattern of bars and spaces, barcode readers can decipher the encoded information.

Unique Characteristics of Different Barcode Symbologies

Now, let’s delve a bit deeper into the fascinating world of barcode symbologies. Each barcode symbology has its own unique characteristics and applications. For example, Code 39 is a popular symbology used in non-retail environments, such as inventory management and healthcare. It can encode alphanumeric characters, making it versatile for various industries.

Another commonly used symbology is Code 128, which is known for its high-density encoding capabilities. Code 128 can encode the entire ASCII character set, allowing for the representation of special characters and extended functionality.

Additionally, there are symbologies like Interleaved 2 of 5, which is often used in logistics and warehousing due to its ability to encode numeric data efficiently. It is called “Interleaved” because it interleaves two digits into each barcode character, resulting in a compact representation of data.

Furthermore, advancements in barcode technology have led to the development of 2D barcodes, which can store significantly more information compared to 1D barcodes. 2D barcodes, such as QR codes, use patterns of squares instead of bars and spaces, allowing for the encoding of text, URLs, and even multimedia content. These barcodes have found widespread use in marketing campaigns, ticketing systems, and contactless payment applications.

As technology continues to evolve, so does the world of barcode technology. From the humble 1D barcode to the sophisticated 2D barcodes, these encoding systems have revolutionized the way we track, identify, and exchange information. Whether it’s scanning products at the grocery store or managing inventory in a warehouse, barcode technology plays a crucial role in streamlining processes and improving efficiency.

Read more: Complete Guide to Warehouse Barcode Systems

The Evolution of 1D Barcode Technology

1D barcode technology has come a long way since its inception. Let’s take a look at how it has evolved over time.

The Birth of 1D Barcodes

The concept of barcodes dates back to the late 1940s when inventors Joseph Woodland and Bernard Silver first explored the idea of using patterns of lines and spaces to represent data. Their invention paved the way for the development of modern barcodes.

However, it wasn’t until the 1970s that barcode technology gained widespread acceptance. The grocery industry, in particular, recognized the potential of barcodes for streamlining the checkout process. Since then, barcodes have become a staple in retail operations worldwide.

Modern Developments in 1D Barcode Technology

Over the years, advancements in technology have led to various improvements in 1D barcode technology. One significant development is the introduction of multiple barcode symbologies, each catering to different needs.

For example, Code 128 barcodes are known for their versatility and can encode both alphanumeric and special characters. This makes them suitable for a wide range of applications, including logistics and inventory management.

Another noteworthy development is the introduction of high-density barcodes, such as the stacked 1D barcode. These barcodes are designed to store more information in a smaller space, making them ideal for applications where limited real estate is available.

Furthermore, advancements in printing technology have also played a crucial role in the evolution of 1D barcode technology. The introduction of high-resolution printers has enabled the creation of more precise and readable barcodes. This has significantly improved the accuracy and efficiency of barcode scanning processes, reducing errors and enhancing overall productivity.

In addition to printing technology, the development of barcode scanning devices has also contributed to the evolution of 1D barcodes. From handheld scanners to mobile devices with built-in barcode scanners, the accessibility and convenience of barcode scanning have greatly improved. This has opened up new possibilities for industries such as healthcare, where barcode technology is used for patient identification, medication tracking, and inventory management.

Looking ahead, the future of 1D barcode technology holds even more exciting possibilities. With the advent of Internet of Things (IoT) and cloud computing, barcodes can be integrated with other technologies to create smart systems that enable real-time tracking, inventory management, and supply chain optimization. These advancements will continue to revolutionize industries and enhance efficiency in various sectors.

How 1D Barcode Technology Works

Now that we have a solid understanding of the basics, let’s explore how 1D barcode technology actually works.

The Scanning Process

The scanning process begins when a barcode reader emits a beam of light onto the barcode. As the light reflects off the bars and spaces, a sensor in the barcode reader detects the reflected light. The sensor converts the light intensity into electrical signals, which are then decoded by the reader.

During the scanning process, the barcode reader measures the width of each bar and space, converting them into binary data. By analyzing the pattern of ones and zeros, the reader can identify the encoded information.

Decoding the Information

Once the barcode reader has captured the binary data, it decodes it into a human-readable format. This decoding process involves mapping the binary data to its corresponding characters, numbers, or special symbols, depending on the barcode symbology used.

For example, an EAN barcode encodes a 13-digit number, which typically represents a product’s unique identifier. The barcode reader decodes the binary data and displays the corresponding numbers, allowing users to identify the product.

Different Types of 1D Barcodes

1D barcode technology encompasses various types of barcodes, each serving a specific purpose. Let’s explore some of the most commonly used types.

EAN Barcodes

EAN barcodes, also known as European Article Numbers, are widely used in the retail industry. They consist of a 13-digit number, which includes a country code, manufacturer code, and product code. EAN barcodes are used to uniquely identify products and facilitate inventory management.

UPC Barcodes

UPC barcodes are predominantly used in North America and are recognized by their 12-digit format. Similar to EAN barcodes, UPC codes help identify products and streamline the checkout process. They are commonly found on grocery items and retail products.

Code 128 Barcodes

Code 128 barcodes are known for their versatility. They can encode a wide range of characters, including uppercase letters, lowercase letters, numbers, and special symbols. Code 128 barcodes are commonly used in logistics, inventory management, and order tracking.

Applications of 1D Barcode Technology

1D barcode technology finds application in various industries and sectors. Let’s explore some of the key areas where it plays a vital role.

Retail and Inventory Management

In the retail industry, barcodes are used to track inventory, manage stock levels, and streamline the checkout process. By scanning barcodes, retailers can quickly identify products, update their inventory systems, and simplify the purchasing process for customers.

Libraries and Bookstores

In libraries and bookstores, barcodes serve as a means of efficiently managing books and other materials. By scanning barcodes, librarians and bookstore employees can easily locate, check out, and return items. Barcodes also enable automated sorting and inventory management, making these processes more efficient.

Ticketing and Boarding Passes

Barcodes are widely used in the transportation industry for ticketing and boarding pass purposes. Whether boarding a plane, train, or bus, passengers can present their digital or printed barcode for quick and seamless check-in. This eliminates the need for physical tickets and reduces waiting times.

Enhancing Barcode Efficiency with Logimax Warehouse Management Software

As we’ve explored the pivotal role of 1D barcodes in various sectors, it’s clear that the right technological support can amplify the benefits these tools offer. At Logimax, we specialize in providing robust Warehouse Management Software (WMS) solutions that perfectly complement and enhance barcode technologies in diverse industries.

Optimized Barcode Scanning with Real-Time Data Collection

Our cloud-based WMS is engineered to streamline operations by integrating seamlessly with barcode scanning systems. This integration ensures real-time data collection and inventory accuracy, crucial for sectors like retail, manufacturing, and logistics. By leveraging barcode technology, Logimax’s software allows for quicker scans, reducing errors and enhancing the checkout and inventory management processes.

Tailored Solutions Across Industries

- Retail & Consumer Goods: Optimize retail operations with our WMS, designed for omnichannel excellence. Our system ensures efficient inventory management and timely order fulfillment, supported by 1D barcode scanning that speeds up operations and minimizes discrepancies.

- Cold Storage: Manage cold storage logistics with precision. Our software supports 1D barcodes to maintain accurate tracking of goods through temperature-controlled environments, ensuring compliance and efficiency.

- Manufacturing & Distribution: Boost productivity with our browser-based system that excels in managing complex manufacturing and distribution processes. Enhanced by 1D barcode integration, our WMS supports streamlined operations from production to point-of-sale.

- 3PL and More: For third-party logistics providers, our WMS offers comprehensive solutions that improve billing, reporting, and inventory management, all optimized by barcode technology for faster, more reliable processing.

Seamless Integration and Support

Understanding the importance of comprehensive system integration, Logimax excels in integrations for ERP, accounting systems, ecommerce, and efficient shipping logistics management. Our advanced API and EDI capabilities ensure that our software can communicate effectively with your existing systems, empowering your operations with minimal disruption.

Conclusion

In conclusion, 1D barcode technology has revolutionized the way we track, manage, and process information. By encoding data into patterns of bars and spaces, barcodes enable efficient scanning, decoding, and retrieval of information. From retail operations to libraries and ticketing systems, barcodes have become an essential tool in various industries. As technology continues to advance, we can expect further innovations and improvements in barcode technology, making our lives more convenient and efficient.

At Logimax, we enhance these innovations with our Warehouse Management Software (WMS), tailored to meet the specific needs of various industries. By integrating with barcode systems, our solutions streamline operations, enhance efficiency, and reduce errors, empowering your business to achieve unparalleled operational excellence. Explore how our intuitive, flexible, and affordable WMS can transform your barcode-based processes. Discover more about our solutions and how we can help you by visiting our dedicated industry pages or contacting us for a personalized consultation.