Understanding Lot Number Inventory Tracking

In the complex world of warehouse and inventory management, lot number inventory tracking stands as a critical function that directly impacts your bottom line. This systematic approach to monitoring specific batches of products throughout the supply chain ensures businesses can maintain quality control, comply with regulations, and protect their profit margins. Unlike standard inventory management that may only track quantities, lot control provides deeper visibility into product batches, their origins, manufacturing dates, and movement through your supply chain.

Lot numbers differ significantly from SKUs and serial numbers in both purpose and application. While SKUs identify product types and serial numbers track individual items, lot numbers identify specific production batches or groups manufactured under identical conditions. This distinction becomes crucial for businesses handling perishable goods, pharmaceuticals, or products subject to quality variations between manufacturing runs. For regulated industries like food production, pharmaceuticals, and medical devices, lot tracking isn’t just beneficial—it’s mandatory for compliance with FDA, USDA, and other regulatory frameworks.

High-value inventory particularly benefits from robust lot control systems. When products represent significant investment, the ability to trace specific batches can prevent costly write-offs and enable targeted recalls if quality issues arise. This precision allows businesses to maintain inventory integrity while minimizing financial exposure from spoilage, obsolescence, or compliance failures—all direct threats to profit margins in competitive markets.

Benefits of Lot Control in Inventory Management

Implementing comprehensive lot number inventory tracking delivers measurable benefits that directly protect your profit margins. Perhaps most significantly, lot control dramatically reduces inventory shrinkage and obsolescence—two persistent challenges that erode profitability in warehouse operations. With accurate lot tracking, businesses can implement first-expired-first-out (FEFO) protocols, ensuring that older inventory moves before newer stock, thereby minimizing waste from expired products. This systematic approach to inventory rotation has been shown to reduce write-offs by up to 35% in industries handling perishable or date-sensitive materials.

The financial implications of effective lot control extend beyond simple waste reduction. When warehouse managers can precisely identify the location and status of specific product batches, they gain powerful tools for margin protection. Consider the case of a food distributor that implemented lot tracking and subsequently reduced their annual inventory losses by $120,000 through better expiration date management. Similarly, manufacturers using lot control can quickly isolate and address quality issues in specific production runs without disrupting their entire inventory, preserving both product availability and profit margins during potential quality incidents.

Lot tracking also enhances inventory valuation accuracy, which directly impacts financial reporting and decision-making. Without proper lot control, businesses often struggle to account for inventory with different costs or values based on production dates or supplier batches. This imprecision leads to financial distortions that can mask margin erosion until it becomes severe. By contrast, organizations with robust lot tracking can precisely value their inventory assets, identify margin compression early, and take corrective action before profitability suffers significantly.

Implementing Effective Lot Tracking Processes

Successful lot number inventory tracking requires thoughtful integration into existing warehouse workflows. Begin by conducting a thorough assessment of your current processes, identifying critical control points where lot information must be captured or verified. These typically include receiving, putaway, picking, packing, and shipping operations. Developing standardized procedures for each of these touchpoints ensures consistent data collection and maintenance of lot traceability throughout the product lifecycle in your facility.

Training represents another crucial element in lot control implementation. Warehouse personnel must understand not just the mechanics of recording lot information but also the business implications of accurate tracking. Effective training programs emphasize both the technical aspects of lot recording and the reasons behind the practice, helping staff recognize their role in protecting company margins through diligent lot management. This dual focus on process and purpose significantly increases adoption rates and accuracy in daily operations.

![]()

On the technology front, modern warehouse management systems (WMS) offer powerful lot tracking capabilities that streamline implementation. Look for features like automated lot assignment during receiving, lot-specific directed putaway that considers expiration dates, and picking algorithms that prioritize inventory based on lot attributes. Mobile scanning technology further enhances accuracy by eliminating manual data entry, with some systems reducing lot tracking errors by up to 67% compared to paper-based methods. Integration capabilities are equally important, ensuring your lot tracking data flows seamlessly between warehouse operations, accounting systems, and quality management platforms.

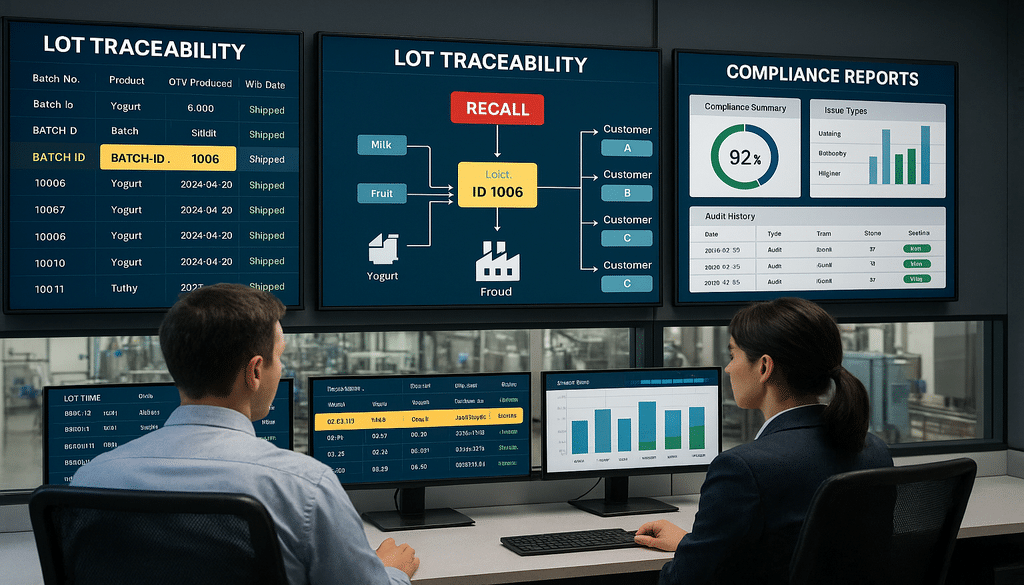

Compliance, Traceability, and Recalls

Regulatory compliance represents one of the most compelling reasons to implement robust lot number inventory tracking. Industries from food and beverage to pharmaceuticals and medical devices operate under increasingly stringent traceability requirements imposed by agencies like the FDA, USDA, and their international counterparts. The Food Safety Modernization Act (FSMA), for example, requires manufacturers to track products one step forward and one step back in the supply chain—a mandate that can only be fulfilled through systematic lot control. Without proper lot tracking, companies risk substantial penalties, operational shutdowns, and severe damage to both their finances and reputation.

Beyond regulatory requirements, lot tracking provides the foundation for effective recall management—an unfortunate but inevitable reality for many businesses. When quality issues arise, companies with granular lot control can precisely identify affected products, limiting recalls to specific batches instead of entire product lines. This targeted approach dramatically reduces recall costs, which can otherwise run into millions of dollars for widespread actions. A pharmaceutical company that implemented advanced lot tracking was able to reduce the financial impact of a recent recall by 78% by limiting the action to specific affected lots rather than all products manufactured within a three-month window.

The downstream benefits of strong lot traceability extend to customer relationships and brand reputation. Businesses that can demonstrate complete product traceability build greater trust with both retail partners and end consumers. This confidence becomes particularly valuable during industry-wide safety concerns or when competitors experience quality issues. The ability to quickly provide definitive information about product origins and manufacturing conditions often becomes a competitive differentiator, allowing businesses to maintain or even increase their market share during periods of industry turbulence—directly protecting profit margins when they might otherwise face pressure.

Optimizing Margin Protection with Lot Control

The data generated through comprehensive lot number inventory tracking creates opportunities for advanced analytics that directly impact profitability. By analyzing lot-specific information about product movement, shelf life, and customer acceptance, businesses can refine their purchasing and production scheduling to minimize holding costs while maintaining service levels. Some organizations have reduced inventory carrying costs by 15-20% through these data-driven optimizations, directly improving cash flow and operational margins without compromising product availability.

Effective lot control also enables more sophisticated pricing strategies based on product attributes and remaining shelf life. Retailers and distributors can implement dynamic pricing models that maximize revenue from inventory approaching expiration dates, recovering value that would otherwise be lost to obsolescence. This approach is particularly valuable in industries with seasonal demand patterns or products with strict dating requirements. A specialty foods distributor implemented such a strategy and increased their recovery on near-date inventory by 45%, substantially improving their overall margin performance despite operating in a highly competitive market segment.

Case studies consistently demonstrate the margin protection value of advanced lot control. A medical device manufacturer implemented lot-level tracking throughout their supply chain and identified $350,000 in annual savings through reduced waste and more efficient inventory deployment. Similarly, a consumer packaged goods company leveraged lot tracking data to optimize their production batch sizes, reducing changeover costs while maintaining freshness requirements. This optimization yielded a 3.2% improvement in gross margins—a significant gain in an industry where margins are typically measured in single digits. These examples illustrate the tangible financial benefits that come from treating lot tracking not just as a compliance requirement but as a strategic tool for margin protection.

Conclusion

Robust lot number inventory tracking represents far more than a technical warehouse function—it’s a strategic capability that directly protects and enhances profit margins across operations. The ability to precisely manage inventory based on production batches, expiration dates, and quality attributes delivers measurable financial benefits through reduced waste, improved compliance, and optimized inventory deployment. As supply chains grow more complex and regulations more stringent, the value of effective lot control will only increase.

Organizations seeking to strengthen their competitive position should evaluate their current lot tracking capabilities against industry best practices and compliance requirements. By identifying gaps and implementing appropriate process and technology improvements, businesses can transform lot control from a necessary operational function into a source of margin protection and competitive advantage. Whether your goal is reducing obsolescence, streamlining recalls, or enhancing customer confidence, investing in advanced lot number inventory tracking provides returns that flow directly to your bottom line.

Frequently Asked Questions (FAQ)

What is the difference between lot number and serial number tracking in inventory management?

Lot number tracking groups items produced in the same batch, allowing you to track and trace products based on production or receipt date. This is useful for managing perishable goods or complying with regulatory requirements. Serial number tracking, on the other hand, assigns a unique code to each individual item, making it ideal for high-value or warrantied products that require one-to-one tracking. While lot tracking manages inventory in batches, serial number tracking is focused on item-level traceability. Most regulated industries require both systems working in tandem for complete product lifecycle documentation.

How does lot number inventory tracking improve warehouse efficiency?

Lot tracking improves warehouse efficiency by enabling more precise inventory location and rotation strategies. With proper lot control, warehouses can implement directed putaway that considers expiration dates, optimize picking routes based on FEFO principles, and reduce time spent searching for specific product batches. This precision typically reduces picking errors by 23-30% and improves inventory turns by enabling confident stock rotation. Additionally, lot tracking streamlines receiving and quality control processes by providing clear documentation of product origins and manufacturing details, reducing processing time and associated labor costs.

What industries benefit most from implementing lot control systems?

While lot control benefits virtually all inventory-based operations, certain industries see particularly high returns on implementation. Food and beverage, pharmaceuticals, medical devices, cosmetics, and chemical manufacturing top the list due to regulatory requirements and product characteristics. Agriculture and fresh produce supply chains also benefit significantly through improved freshness management and compliance with farm-to-table traceability regulations. Additionally, any industry handling products with expiration dates, batch-specific quality variations, or high recall costs will find lot tracking essential for both compliance and margin protection.

How can small businesses implement effective lot tracking without large technology investments?

Small businesses can implement effective lot tracking by starting with a phased approach that prioritizes high-risk or high-value products. Begin with standardized lot number formats and manual tracking using spreadsheets or basic inventory software with lot fields. Cloud-based inventory management solutions offer affordable options with lot tracking capabilities that scale with your business. Focus first on core processes like receiving and shipping documentation, then gradually implement more sophisticated rotation and picking strategies. Even with limited technology, consistent staff training and clear standard operating procedures for lot recording and verification can establish effective lot control that protects margins and ensures compliance.

What metrics should businesses track to measure the effectiveness of their lot control systems?

To evaluate lot control effectiveness, track metrics like inventory accuracy at the lot level (target: >99%), obsolescence/shrinkage as a percentage of inventory value, average time to locate specific lots, recall response time and scope, and regulatory compliance incidents. Also monitor operational metrics like put-away and picking accuracy rates for lot-controlled items, percentage of inventory moved according to FEFO principles, and labor hours associated with lot tracking activities. Finally, measure financial impacts through metrics like carrying cost reductions, recovered value from near-date inventory, and cost avoidance from targeted (versus broad) recalls. These indicators collectively demonstrate both operational effectiveness and financial return on lot control investments.